We stock or have quick access to Hardwood Plywood panels in all grades, veneer species and core types, ranging in thickness from 1/8” to 1-1/2”. We can also supply you with Moisture Rated, Fire Rated, and No-Added Urea Formaldehyde (NAUF) hardwood plywood. Our products manufacture fine furniture, commercial fixtures, high-end cabinetry, architectural millwork, and more interior surfaces. We can also supply you with Pre-Finished hardwood plywood panels, both imported and domestic variations.

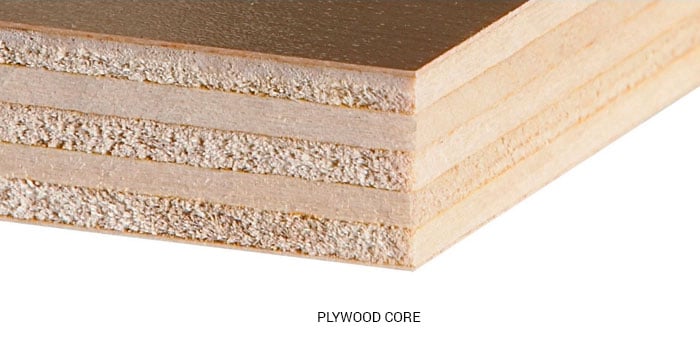

Veneer Core

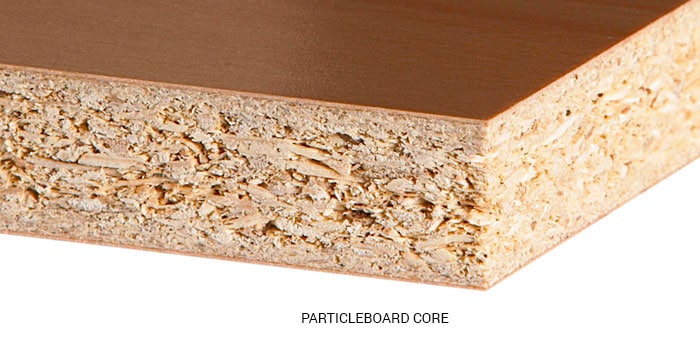

PBC is one of the heaviest and least expensive core option for hardwood plywood, offering a smooth, void-free surface for veneer faces. However, it offers the least structural strength and is subject to the greatest amount of expansion if exposed to moisture. PBC wood particles are bonded with urea formaldehyde or, by special order NAUF PBC.

Medium Density Fiberboard (MDF) Core

MDF is similar to PBC, but the particles are smaller and more uniform, thus offering great stability, and is less likely to warp or expand when subject to a change in temperature or humidity. MDF core is also stronger than PBC and offers more screw holding properties. MDF products are most often manufactured with urea-formaldehyde resins, however we also carry NAUF MDF core products.

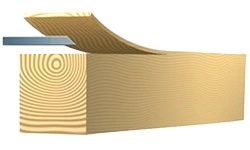

VENEER CUTS METHODS

Flat Cut / Plain Slicing

This is the most common method of veneer manufacturing, producing a grain pattern known as cathedral. Because each leaf in the flitch is similar, a consistent and even matching pattern is possible. Flat cut veneer is ideally suited for wall panels and furniture.

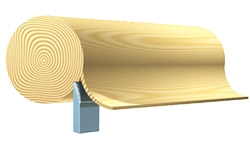

Rotary Slicing

The log is turned in a circular motion against a knife, peeling off a continuous thin sheet of wood veneer (like unrolling wrapping paper). It is the most economical method of producing veneer, resulting in the highest yield. The grain is inconsistent and leaves are most difficult to match. This type of veneer is best suited for paint grade or utility surfaces.

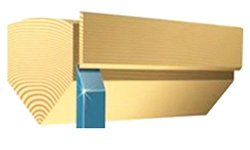

Quarter Sawing/ Slicing

is a process in which logs are cut (or veneer is sliced) into quarters and then the boards (or veneer) are sawn (or sliced) at an angle away from the center of the log. This causes the growth rings, or grains, to pass through the boards at a more perfect 90 degree angle.

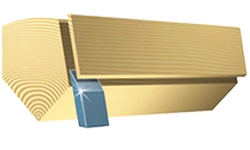

Rift Cutting/ Rift Sawing

Produced by cutting at a slight angle to the radial to produce a quartered appearance without excessive ray flake. The rift cut method, commonly used for Oak, can only be used on sizable logs. Rift cut veneer can easily be sequenced and matched. This also produces lumber of great stability. However, since this produces a great deal of waste, (in the form of wedge-shaped scraps from between the boards), rift-sawing is much less-commonly used than flat sawing and quarter sawing.

VENEER ASSEMBLY METHODS

Book Matching

Alternating pieces of veneer are flipped over so the two adjoining surfaces mirror each other, giving the appearance of an open book. This is the most common type of matching. Because the “tight” and “loose” faces alternate in adjacent leaves, they reflect light and accept stain differently, which may produce a noticeable color variation in some species or flitches.

Butt or End Matching

Veneer leaves are spliced end to end to create a longer panel or piece of veneer. There are two types of end matching: Architectural end matching – where leaves are first book or slip matched end-to-end and then side-to-side, alternating end and side.

Center Matching

Each panel face is made with an even number of flitch sheets with a center line appearing at the midpoint of the panel and an equal number of veneer sheets on each side of the center line. The number of leaves on the face is always even, but the widths are not necessarily the same.

Random Matching / Planked

Veneer are placed next to each other to purposefully mismatch grain, color, size, and pattern. This often produces a casual or rustic appearance as it is trying to simulate lumber planking.

Running Match

The panel face is made from components running through the flitch consecutively. Any portion of a component or leaf in starting the next panel.

Sequence Matching

A method of arranging veneer faces such that each face is in order relative to its original position the tree and, therefore, contains features of grain and figures similar to adjacent faces.

Slip Matching

Means that veneer leaves in a flitch are “slipped.” Successive veneer leaves in a flitch are “slipped” one alongside the other and edge-glued in this manner. The result is a series of grain repeats, but no pairs. The danger with this method derives from the fact that grain patterns are rarely perfectly straight. Sometimes a grain pattern “runs off” the edge of the leaf. A series of leaves with this condition could usually make a panel look like it is leaning. In the book matching the pairs balance each other. However, since all faces have the same light refraction, there will be a uniformity of color, unlike book matching.

With respect to real wood and reconstituted wood veneer; variations in color, figure, and other natural characteristics can occur. Wood is a natural product and will always exhibit individual features and character marks. The overall look of the product can also vary depending on the cut and matching method utilized. Please contact a Formations sales representative if you require a specific ‘look’ or need to match an existing wood or reconstituted wood veneer.

Pleasing Match

Veneer is matched by color but not by grain pattern.

Get a Quote

Looking to get a quote for your next project?

Get A Quote

Locations